How AI Improves Food Safety with Temperature Control

• Updated

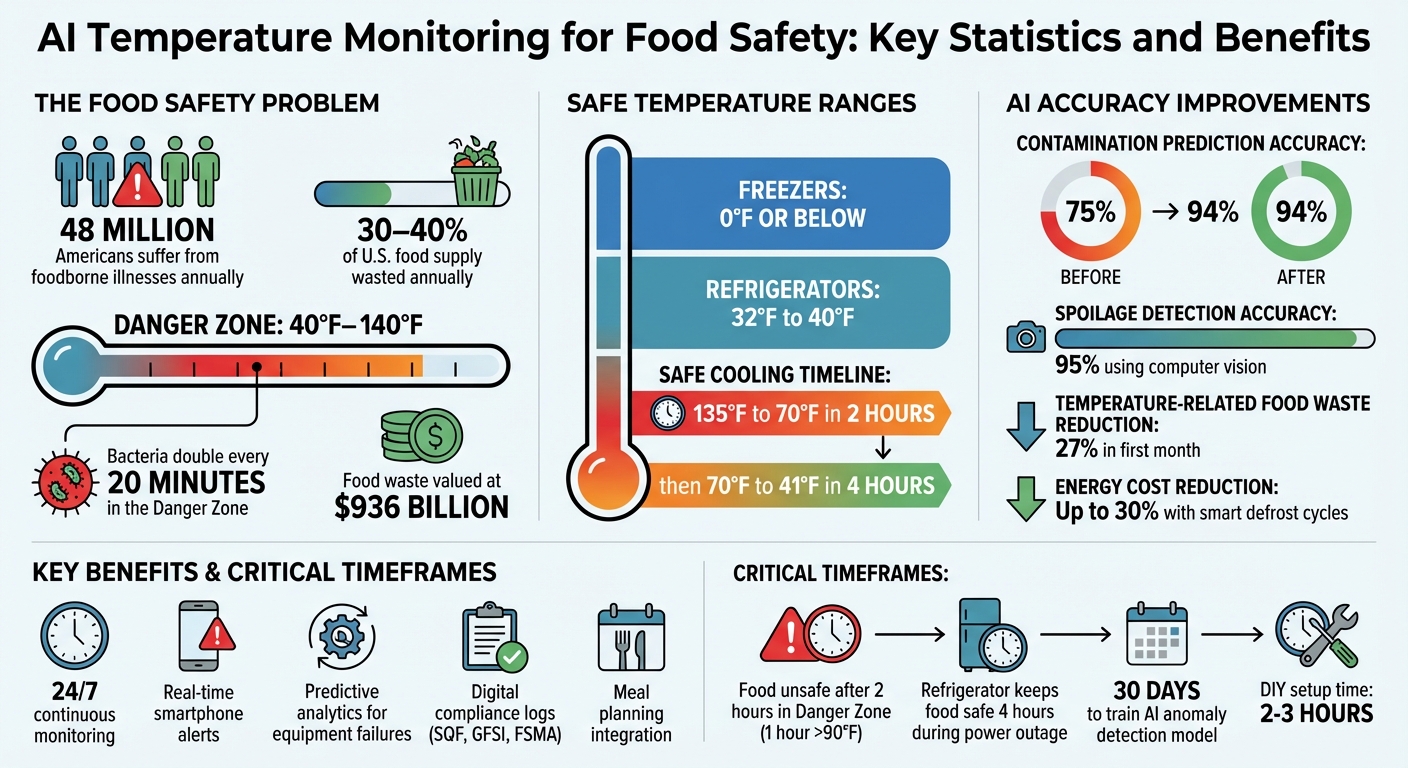

Food safety starts with proper temperature control. Each year, 48 million Americans suffer from foodborne illnesses, often due to poor handling of food temperatures. The "Danger Zone" (40°F–140°F) is where bacteria like Salmonella and E. coli multiply quickly, doubling every 20 minutes. Many rely on visual cues to judge food safety, but this can lead to mistakes.

AI-powered temperature monitoring changes the game. Using IoT sensors and machine learning, these systems provide real-time updates, predict risks, and even prevent equipment failures. They alert you if your fridge goes above 40°F, ensure cooked food cools safely, and help avoid spoilage. For home cooks, this means safer food and less waste.

Key Benefits of AI in Food Safety:

- Continuous Monitoring: Sensors track temperature, humidity, and spoilage risks 24/7.

- Instant Alerts: Notifications warn you of unsafe conditions, like a fridge door left open.

- Predictive Analytics: AI forecasts issues, such as spoilage or equipment breakdowns.

- Meal Planning Integration: Smart tools suggest recipes to use items before they expire.

Whether through DIY setups or smart appliances, AI simplifies food safety, reduces waste, and protects your family’s health.

AI Temperature Monitoring for Food Safety: Key Statistics and Benefits

The Use of Artificial Intelligence (AI) in Food Safety, and What to Expect Next

How AI Temperature Monitoring Works

AI-powered temperature monitoring merges IoT sensors with advanced algorithms to provide constant oversight. Unlike manual checks that capture only a single moment in time, these systems monitor temperature continuously, identifying fluctuations and turning raw data into meaningful insights. This combination of sensors and analytics is at the heart of modern food safety systems.

IoT Sensors and Real-Time Data Collection

IoT sensors keep tabs on temperature, humidity, and spoilage-related gases throughout your kitchen - whether in refrigerators, freezers, or other equipment - and transmit this data in real time.

These sensors often operate without direct contact. For example, some systems use 3D food geometry modeling and thermal profiling to estimate internal temperatures from surface readings, doing away with the need for invasive probes.

One notable example comes from November 2025, when an Irish grocery distributor equipped three delivery vans with LTE-M IoT sensors. These sensors tracked both temperature and vehicle movement in real time, sending alerts whenever the cold chain was at risk. This setup not only reduced food spoilage but also ensured compliance with safety regulations.

AI Analysis and Alerts

Once collected, the data is processed by AI algorithms to create actionable insights. These systems analyze large datasets from IoT sensors to detect early signs of spoilage. Machine learning models like Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks excel at analyzing time-series temperature data, even predicting shelf life based on trends and historical patterns.

Predictive analytics take this a step further. These systems don't just issue alerts for temperature breaches - they also forecast potential risks before they occur. By identifying patterns that could lead to unsafe conditions, businesses can act preemptively to protect food safety.

"By having constant, real-time updates, businesses can immediately address any deviations from the norm, significantly reducing the risk of spoilage and ensuring that only safe, high-quality products reach consumers."

- Radojka Barycki, Food Safety Expert, FoodReady

AI's ability to predict and detect issues is impressive. For instance, a microbial risk assessment system using Random Forest and LSTM networks improved contamination prediction accuracy from 75% to 94%. This demonstrates how AI can catch subtle warning signs that manual methods might miss, especially when it comes to the interplay between temperature, time, and bacterial growth.

Beyond food safety, AI also monitors equipment health. By analyzing cooling cycles and compressor performance, it can predict equipment failures before they lead to spoilage. For example, if a freezer’s compressor starts showing irregular patterns, the system can issue an alert, enabling timely repairs and avoiding costly losses. Additionally, automated systems generate digital logs that comply with standards like SQF, GFSI, and FSMA - removing the risk of errors tied to manual recordkeeping.

Setting Up AI Temperature Monitoring at Home

AI temperature monitoring has become an option for home kitchens, offering two main approaches: DIY systems using microcontrollers or smart appliances with built-in AI features. DIY setups generally take about 2–3 hours to assemble and configure, while smart appliances provide a simple plug-and-play experience, often paired with manufacturer apps for easy integration. Here’s how to get started with sensor installation and system configuration to bring this technology into your kitchen.

Installing Sensors and Configuring Systems

For those who enjoy DIY projects, the ESP32 microcontroller (like the Adafruit Feather HUZZAH32) is a great starting point. Pair it with components such as high-precision thermocouples and amplifiers like the Adafruit MCP9600 I2C Thermocouple Amplifier for monitoring extreme temperature environments like freezers. To program these systems, you’ll need tools like the Arduino IDE and platforms such as Adafruit IO, which lets you create visual dashboards for real-time temperature tracking.

Proper sensor placement is essential for accurate data. For refrigerators, placing the sensor in a glass of water at the center of the unit helps measure the actual food temperature rather than the fluctuating air temperature. In freezers, positioning the sensor between frozen packages ensures better accuracy. After installation, allow 5–8 hours for the sensor to stabilize before relying on the data or calibrating your AI model. Set alerts to notify you if the refrigerator exceeds 40°F or if the freezer rises above 0°F.

"If the thermocouple is moved too far away from the training position, the ML model may mistake normal operation as an anomaly." - Adafruit Learning System

Once your sensor is in place and ready for training, avoid moving it. Changing its position can confuse the AI model and lead to false alarms. Generally, custom AI anomaly detectors need about 30 days of passive temperature data collection to build a reliable model.

Customizing Alerts and Notifications

To make your system more practical, configure alerts using services like IFTTT (If This Then That), which can send notifications via SMS, email, or even trigger smart devices like lights. Use WiFi for continuous monitoring of devices such as freezers or slow cookers, while Bluetooth works well for short-range tasks like grilling.

Modern AI systems are smart enough to differentiate between normal temperature changes - like a refrigerator’s defrost cycle - and actual equipment malfunctions, helping reduce unnecessary alerts. Customize your alert thresholds based on your needs: general cooking might allow temperature variations of ±1.8°F, while precise baking may require stricter control, such as ±0.5°F. Lastly, for DIY setups, store sensitive information like WiFi passwords and API keys in a separate configuration file to keep your system secure.

Preventing Temperature-Related Food Safety Issues

Temperature control plays a crucial role in food safety, covering everything from storage to serving. AI-powered monitoring systems are changing the game for home cooks, helping to prevent common temperature-related risks like foodborne illnesses and spoilage. These systems not only protect your food but also simplify processes like cooling and equipment monitoring.

Avoiding Food Spoilage

Keeping food from spoiling starts with constant temperature monitoring. AI sensors keep an eye on your refrigerator and freezer around the clock, sending real-time alerts to your smartphone if anything goes wrong. For reference, freezers should stay at or below 0°F, while refrigerators need to maintain a range of 32°F to 40°F. Even a small 2°F fluctuation can spoil delicate ingredients, which is why these automated systems are so important.

Wireless door sensors are another handy feature. They notify you if a freezer door is left open or isn’t sealed properly, preventing the slow rise in temperature that can ruin stored food. Considering that 30% to 40% of the U.S. food supply is wasted annually, a loss valued at about $936 billion, catching these issues early saves both money and groceries.

Managing Cool-Down Processes for Cooked Foods

Proper cooling is just as important as proper storage, especially for cooked foods. Bacteria thrive in the temperature range of 40°F to 140°F, making this the danger zone for food safety. Smart thermometers that stay in the food during cooling provide live updates to your phone, helping you stick to the two-stage cooling rule: food must drop from 135°F to 70°F within 2 hours, and then from 70°F to 41°F within the next 4 hours.

"Leaving food out too long at room temperature can cause bacteria (such as Staphylococcus aureus, Salmonella Enteritidis, Escherichia coli O157:H7, and Campylobacter) to grow to dangerous levels that can cause illness." - USDA Meat and Poultry Hotline

If your system alerts you that the food hasn’t cooled to 70°F within the first 2 hours, you’ll need to reheat it to 165°F for at least 15 seconds to restart the cooling process - or discard it entirely. These automated tools eliminate the guesswork and reduce the chance of human error.

Detecting and Responding to Equipment Failures

AI also shines when it comes to spotting equipment issues before they lead to spoiled food. For instance, monitoring power spikes with AC meters can reveal failing compressors or motors. Similarly, differential air pressure sensors can detect ventilation problems in freezers, alerting you to blocked fans or systems struggling to maintain subzero temperatures.

"A sharp spike in power draw might be a signal that your cold chain management equipment requires servicing." - Monnit

After a power outage, refrigerators can only keep food safe for about four hours if the doors remain closed. AI systems with internet connectivity can send alerts during outages, allowing you to act even if you’re not home. Plus, digital logs track high-temperature records, so you’ll know if your equipment had trouble overnight or while you weren’t paying attention.

Smart Features for Food Preservation

Smart technology takes food preservation beyond simple temperature monitoring. AI-powered refrigerators not only track conditions but also actively maintain the ideal environment for your food. By combining computer vision, predictive modeling, and advanced sensors, these systems adapt to the specific needs of the items stored inside.

Customized Cooling Zones

Modern AI systems are equipped with internal cameras that identify the contents of your fridge and adjust cooling zones automatically. For instance, Samsung's AI Vision Inside 2.0 can recognize 37 types of produce and recommend the best storage spots. It uses AI Hybrid Cooling technology, incorporating smart sensors and Peltier modules, to respond quickly to temperature changes. If the system anticipates a temperature increase within five minutes, it boosts cooling power to stabilize conditions, reducing energy use by up to 10%.

For optimal food preservation, store perishable items like meat and fish in the back of the fridge, where it's colder, and place less sensitive items, like condiments, in the door. Avoid overcrowding shelves, as this can block airflow and create warm spots that even advanced sensors may struggle to regulate. Beyond temperature, other factors like humidity and expiration tracking play a crucial role.

Humidity and Expiration Date Tracking

AI systems also monitor humidity levels and track "use-by" dates, sending alerts as items near expiration. This feature is particularly effective in reducing food waste - institutions using AI temperature intelligence have reported a 27% decrease in temperature-related food waste within the first month of implementation.

"AI-based systems, by processing real-time information, can pave the way for developing novel tools to assess the microbial quality of raw materials used and the shelf life and safety of the food product." - ScienceDirect, Food Control

Proper humidity is essential for keeping produce fresh. AI-driven humidity sensors or smart crisper drawers maintain the right moisture levels, preventing vegetables from drying out and minimizing frost buildup. For packaged foods, manually registering items can help you maintain a complete inventory. These steps also help address freezer-specific challenges.

Frost and Freezer Burn Prevention

Freezer burn happens when moisture migrates during temperature fluctuations. AI tackles this issue by replacing fixed defrost schedules with smart cycles that activate only when necessary. Refrigeration Technologies' ArtikControl™ system, for example, has been shown to cut energy costs by up to 30% in commercial settings by optimizing defrosting.

"AI uses actual system requirements to optimise defrosting operations instead of traditional fixed schedule systems. The system optimises power usage by skipping unneeded energy consumption operations without affecting cooling efficiency." - Haier India

To maximize efficiency, enable AI Energy or Smart modes in your refrigerator. These settings allow the system to learn your usage patterns and adjust performance accordingly. Respond promptly to "door left open" alerts to prevent frost buildup, and follow AI recommendations for organizing frozen items. This ensures proper airflow and consistent cooling, reducing spoilage risks.

Using AI Tools with Meal Planning Apps

AI is making meal planning smarter by combining real-time temperature monitoring with ingredient management. These AI-driven meal planning apps work alongside temperature tracking systems to help you organize your food storage and minimize waste. By linking your refrigerator's data with recipe suggestions, these tools ensure you use perishable items before they spoil. This integration connects temperature control with forward-thinking meal planning, making it easier to reduce food spoilage.

Using Pantry Mode for Ingredient Management

Pantry Mode is a handy feature that lets you snap a photo of your fridge and get recipe ideas based on what's inside. For example, Honeydew Recipe Manager's Pantry Mode uses computer vision to identify ingredients and recommend recipes that focus on perishable items like seafood, dairy, and fresh produce. This approach tackles a major issue: around one-third of all food produced for human consumption is wasted each year due to spoilage.

The technology behind this feature uses Convolutional Neural Networks (CNNs) to spot visual signs of spoilage, such as bruising or mold, with an impressive 95% accuracy. When you take a photo of your fridge, the AI not only identifies the ingredients but also evaluates their condition, helping you decide what needs to be used right away. This is especially useful for items that require refrigeration within 2 hours of being at room temperature - or within 1 hour if it’s hotter than 90°F.

Reducing Food Waste with AI Meal Planning

AI-based meal plans help you use ingredients before they go bad by analyzing your inventory and crafting weekly menus that prioritize items nearing their expiration dates. For instance, Honeydew Recipe Manager creates personalized meal plans that follow cold-storage guidelines. It considers timelines like cooking or freezing fresh poultry within 1 to 2 days of purchase and suggests recipes accordingly.

"Meal-planning apps help [people] save time and money and provide variety in the diet... they can help [people] track their progress and promote healthier eating habits." - Jaime Coffey Martinez, Registered Dietitian and Founder of Nutrition CPR

Machine Learning models, particularly Long Short-Term Memory (LSTM) networks, analyze temperature and humidity data to predict spoilage and extend the shelf life of perishable items. When linked to a meal planning app, these predictions allow the system to adjust your weekly menu automatically. Recipes using at-risk ingredients are moved earlier in the week, which can extend the shelf life of certain foods by up to 2 days. This kind of smart menu adjustment supports the broader goal of keeping food safe and reducing waste through precise storage and planning.

Responding to Alerts and Maintaining Records

Understanding and Acting on Temperature Alerts

When an AI temperature alert pops up, quick action is critical. Food sitting in the Danger Zone (40°F–140°F) creates the perfect environment for bacteria to multiply - doubling every 20 minutes. If food stays in this range for more than two hours, the USDA advises throwing it out. Why? Heat-resistant toxins can develop, and cooking won’t eliminate them.

Start by verifying the alert. Check that the probe is placed in the thickest part of the food, avoiding bones or fat, and confirm the temperature using an appliance thermometer. If the reading still shows above 40°F, take action immediately. Keep in mind, if the surrounding temperature is above 90°F, the safe window shrinks to just one hour.

"Leaving food out too long at room temperature can cause bacteria (such as Staphylococcus aureus, Salmonella Enteritidis, Escherichia coli O157:H7, and Campylobacter) to grow to dangerous levels that can cause illness." - USDA Meat and Poultry Hotline

If the issue stems from equipment failure rather than a genuine temperature problem, act fast to prevent spoilage. Move perishable items to a working fridge or an iced cooler. For frozen foods, check for ice crystals - if they’re still there, the food can be safely refrozen. If you haven’t already calibrated your sensors, now is a good time. Use the ice water method (32°F) or the boiling water method (212°F at sea level) to confirm sensor accuracy.

Keeping Digital Records for Food Safety

Keeping track of temperature data isn’t just about responding to alerts - it's about spotting patterns and preventing future issues. Digital logs create a reliable, time-stamped record of storage conditions, eliminating manual errors and highlighting any unsafe temperature exposures.

Centralize your records in a digital dashboard so you can quickly spot trends. For example, if your freezer shows small temperature spikes at the same time each day, it might point to a door seal problem that needs fixing before it gets worse. Regularly update calibration logs for each sensor to ensure accuracy and traceability. These records aren’t just useful for day-to-day monitoring - they’re invaluable during recall investigations or when troubleshooting ongoing storage issues.

Conclusion

AI-driven temperature control is changing how we approach food safety at home. With real-time monitoring powered by IoT sensors, temperature fluctuations are detected and addressed before they become a problem. Predictive models also play a role, helping forecast spoilage and extending the lifespan of your groceries. This hands-on approach not only improves daily kitchen routines but also tackles major public health concerns.

The urgency of maintaining proper kitchen temperatures is backed by statistics. For instance, when your refrigerator temperature rises above 40°F or your freezer fails during a power outage, smart sensors send immediate alerts. This allows you to act quickly, preventing the growth of harmful bacteria.

On top of safety, these AI tools help cut down on food waste. By keeping digital records, you can identify recurring temperature issues that might signal equipment malfunctions. Pairing these records with smart meal planning takes things a step further, offering a dual benefit of safety and better inventory management. Honeydew Recipe Manager exemplifies this integration. Its Pantry Mode lets you snap a photo of your fridge and instantly get recipe ideas based on what you have. Plus, its AI-powered meal planning ensures you use items before they spoil, making it an affordable and practical addition to your kitchen routine.

The reassurance this technology provides is invaluable. You’ll no longer have to guess if leftovers are safe to eat or worry about whether a brief power outage ruined your frozen goods. Automated alerts and digital logs take care of the monitoring, freeing you to focus on cooking rather than stressing over food safety.

Whether you start with a simple smart sensor or dive into tools like Honeydew Recipe Manager, AI technology offers an easy way to make your kitchen safer, more efficient, and less wasteful.

FAQs

How can AI detect and prevent food spoilage?

AI has the ability to monitor and prevent food spoilage by analyzing data from sensors that track essential factors such as temperature, humidity, and gas emissions. By recognizing shifts or patterns in these conditions, AI systems can predict when food is likely to spoil and notify users to intervene.

This technology plays a crucial role in keeping food safe, whether at home or in commercial kitchens. It helps ensure ingredients remain fresh and minimizes waste. For instance, AI-powered devices can assist home cooks by keeping an eye on storage conditions, making meal preparation both safer and more convenient.

How does AI help improve food safety with temperature control at home?

AI is making it easier to ensure food safety at home by providing precise temperature monitoring and control. These systems actively track and adjust temperatures in real-time, reducing the risk of bacterial growth and spoilage. This means your food stays fresh longer, remains safe to eat, and helps lower the chances of foodborne illnesses.

Beyond just temperature control, AI-powered tools can optimize storage by creating specialized cooling zones tailored to different types of food. For example, vegetables, dairy, and meats can each be stored at their ideal temperature, which extends their shelf life, cuts down on waste, and saves money in the long run. Many of these systems also connect to smart devices, offering alerts and insights that make managing food storage a breeze for home cooks.

For those looking to simplify meal planning, tools like Honeydew Recipe Manager use AI to streamline kitchen tasks. From importing recipes to organizing meal plans and managing grocery lists, these tools not only enhance your cooking experience but also help you maintain food safety without extra effort.

How does AI help reduce food waste at home?

AI is becoming a handy kitchen assistant, helping you cut back on food waste by making meal planning and pantry management easier. Tools like Honeydew Recipe Manager are designed to track the ingredients you already have and suggest recipes that use items close to their expiration date. This way, you can avoid spoilage and make better use of your groceries.

These tools go a step further by generating smart grocery lists based on what’s already in your pantry. This helps you shop more efficiently, preventing overbuying and unnecessary waste. On top of that, AI can offer creative ideas for turning leftovers into entirely new dishes, saving you money while keeping waste to a minimum. With AI’s help, you can cook smarter and create a kitchen that’s both efficient and waste-conscious.